Saturday, September 30, 2006

Ah yes, Mario Latowski is coming to San Francisco's Mr. S today to measure people for his famous chastity belts! My appointment with him is coming up soon, so I have to get out the door!!!

I've gone with impatience and foregone the second coat of silicone.

I've taken some of the aforementioned ancient Bondo resin and mixed it with some equally ancient hand-chopped fiberglass and smeared it over the cured silicone. The clay prototype is still inside.

No, it doesn't look pretty does it? If you look closely, you might be able to see some stray glass fibers. I am a little concerned about my ability to pull the stick out, which reminds me that I'd better clear out the area where the key turns.

Hopefully when the resin cures, I can peel the lot off the plastic drop cloth, cut off the excess silicone, then I'll have a nice rigid mold for the second half of my prototype.

I've taken some of the aforementioned ancient Bondo resin and mixed it with some equally ancient hand-chopped fiberglass and smeared it over the cured silicone. The clay prototype is still inside.

No, it doesn't look pretty does it? If you look closely, you might be able to see some stray glass fibers. I am a little concerned about my ability to pull the stick out, which reminds me that I'd better clear out the area where the key turns.

Hopefully when the resin cures, I can peel the lot off the plastic drop cloth, cut off the excess silicone, then I'll have a nice rigid mold for the second half of my prototype.

Found some ancient Bondo Resin and fiberglass cloth.

I mixed a sample of the ancient resin with some of catalyst to see whether it's still good.

I have now learned never to mix resin in a styrofoam cup because the styro can't take the heat and disintegrates!

Ah well, the resin mix is now curing in my plant tray. I'll find out how well it works tomorrow...

I mixed a sample of the ancient resin with some of catalyst to see whether it's still good.

I have now learned never to mix resin in a styrofoam cup because the styro can't take the heat and disintegrates!

Ah well, the resin mix is now curing in my plant tray. I'll find out how well it works tomorrow...

My trip to TAP Plastics was a success! I have more mold making stuff, some epoxy resin to play with, a urethane foam kit in case I decide to use it, some opaque red dye for the external coat, 1200 and 2400 grit sandpaper, and mold release spray. The marine epoxy was tempting for its claim to be a non-odourous product, but the store guy said that the slightly cheaper general-use epoxy will suit my purposes.

On with the show:

Instead of making a mold out of solid silicone like last time, I'm going to try a different technique to save on that expensive stuff and back a thin layer of silicone with a hard fiberglass shell.

I made the matching part for the prototype locking mechanism out of modelling clay and I've poured 2 fl. oz. of RTV silicone mold making compound over it:

As you can see, 2 fl. oz was way too much and it made a big mess.

Now do I go for a second coat of silicone, or pour the supporting resin with a little chopped fiberglass over it?

It's late for a decision and the silicone is still curing anyway.

Next time, I'll definitely have to get the Fast Cure catalyst instead of the Regular...

G'nite!

On with the show:

Instead of making a mold out of solid silicone like last time, I'm going to try a different technique to save on that expensive stuff and back a thin layer of silicone with a hard fiberglass shell.

I made the matching part for the prototype locking mechanism out of modelling clay and I've poured 2 fl. oz. of RTV silicone mold making compound over it:

As you can see, 2 fl. oz was way too much and it made a big mess.

Now do I go for a second coat of silicone, or pour the supporting resin with a little chopped fiberglass over it?

It's late for a decision and the silicone is still curing anyway.

Next time, I'll definitely have to get the Fast Cure catalyst instead of the Regular...

G'nite!

Thursday, September 28, 2006

I have some pictures of the prototype part. It's still curing, so you'll see some fingerprints on the surface, but those will come out if I choose to sand this thing.

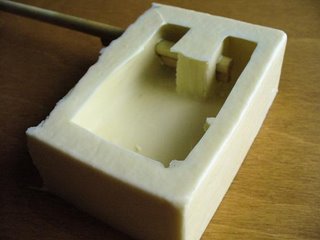

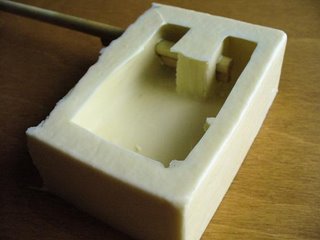

First, a shot of the mold itself with the dowel for the keyhole inserted:

Next, a shot of the entire piece resting on the mold:

Last, a closeup of the entrance to the locking mechanism:

Fascinating stuff, huh? :-)

The next step is to cast the matching part for which I'll need more mold making supplies. I'm having trouble getting Alumilite products from my local hobby shop, so as much as I hate chain stores, I'll hit my local TAP Plastics for some silicone mold stuff and an epoxy kit.

First, a shot of the mold itself with the dowel for the keyhole inserted:

Next, a shot of the entire piece resting on the mold:

Last, a closeup of the entrance to the locking mechanism:

Fascinating stuff, huh? :-)

The next step is to cast the matching part for which I'll need more mold making supplies. I'm having trouble getting Alumilite products from my local hobby shop, so as much as I hate chain stores, I'll hit my local TAP Plastics for some silicone mold stuff and an epoxy kit.

I've spent about an hour synchronizing my collection of Insex videos. When I first ran across them, they struck me as being harsh, but the more I watch them, the more I'm convinced that PD was a good dom. Well most of the time anyway. A few times, I got the impression that he went beyond the model's limits and beyond what I'd consider to be safe S&M play. Like when he suspends models only by a collar around their necks, or when he plays with electricity around a model's chest. You can't get video like that anymore, but that's probably a good thing. Maybe I'm just jaded as fuck right now.

---

Talked to my girlfriend about accepting me as a kinky-type person tonight. I think it went well with us expressing our feelings about that part of my personality. I just went over my latex and crossdressing fetishes and the possibility of introducing her to the others later.

She and I are quite serious, so I'm glad that she's willing to try and put up with it and even experiment with kink together. That's all that I could really ask her to do, so I'm satisfied.

---

I've cast my first prototype piece for the composite chastity belt.

Yesterday, I created a prototype in modelling clay, sealed a cardboard box, and poured silicone molding mix over the prototype to create a mold. Then after the silicone cured, I removed the modelling clay prototype, and poured resin and catalyst into the mold.

I used polyester resin (Castin Craft clear), which is the variety of resin that stinks to high hell like chemicals. Next time, I'll try epoxy resin which is supposed to have much less odor and cure dry to the touch as opposed to polyester which cures tacky. I'm starting to believe that Alumilite resin is a variety of epoxy resin. Being able to use a non-toxic resin is pretty important for something I'm going to be wearing next to my skin, doncha think?

This first piece is just a prototype to test my locking mechanism, so it doesn't really matter what it's made of.

---

Talked to my girlfriend about accepting me as a kinky-type person tonight. I think it went well with us expressing our feelings about that part of my personality. I just went over my latex and crossdressing fetishes and the possibility of introducing her to the others later.

She and I are quite serious, so I'm glad that she's willing to try and put up with it and even experiment with kink together. That's all that I could really ask her to do, so I'm satisfied.

---

I've cast my first prototype piece for the composite chastity belt.

Yesterday, I created a prototype in modelling clay, sealed a cardboard box, and poured silicone molding mix over the prototype to create a mold. Then after the silicone cured, I removed the modelling clay prototype, and poured resin and catalyst into the mold.

I used polyester resin (Castin Craft clear), which is the variety of resin that stinks to high hell like chemicals. Next time, I'll try epoxy resin which is supposed to have much less odor and cure dry to the touch as opposed to polyester which cures tacky. I'm starting to believe that Alumilite resin is a variety of epoxy resin. Being able to use a non-toxic resin is pretty important for something I'm going to be wearing next to my skin, doncha think?

This first piece is just a prototype to test my locking mechanism, so it doesn't really matter what it's made of.

Monday, September 25, 2006

Welcome to my blog! First, let me introduce myself. My name is Alphax (capitalization not required), and I suppose my claim to fame thus far is writing an erotic story called Presents back in 1994 that was well recieved.

Since my adolescence and maybe even before then, I've been sexually turned on by tight and shiny clothes be they satin, PVC, latex, nylon. I've dabbled in being a crossdresser, in corsets, in bridal gowns.

Most recently I've been obsessed by chastity belts. Yes, I guard that wikipedia entry like a hawk!

That brings me to why I've started blogging after lurking for so many years:

I'm building a fiberglass chastity belt based on the defunct Reinholds company's design.

I've spent a lot of time and mental energy coming up with design, materials, and a process for putting everything together and it's been lonely...

So here I am. Throwing it out there and seeing if it sticks.

Hopefully, I'll be able to post updates weekly.

Hope to hear from you soon!

Since my adolescence and maybe even before then, I've been sexually turned on by tight and shiny clothes be they satin, PVC, latex, nylon. I've dabbled in being a crossdresser, in corsets, in bridal gowns.

Most recently I've been obsessed by chastity belts. Yes, I guard that wikipedia entry like a hawk!

That brings me to why I've started blogging after lurking for so many years:

I'm building a fiberglass chastity belt based on the defunct Reinholds company's design.

I've spent a lot of time and mental energy coming up with design, materials, and a process for putting everything together and it's been lonely...

So here I am. Throwing it out there and seeing if it sticks.

Hopefully, I'll be able to post updates weekly.

Hope to hear from you soon!